It is usually used within manufacturing contexts to produce hand tools, power tools, stamping dies, axes, pickaxes, injection molding machinery and other kinds of heavy equipment. Read More…

Delta Steel is a leading provider of high-quality steel products, offering a comprehensive range of steel solutions to meet the diverse needs of our customers. With a commitment to excellence and reliability, we supply a wide variety of steel products for construction, manufacturing, infrastructure, and other industries.

At Delaware Valley Steel, we take pride in being one of the region’s most trusted steel service centers. We have built our reputation on precision, reliability, and the ability to deliver high-quality materials tailored to the unique needs of our customers.

At Grand Steel Products, Inc., we are a leading provider of steel service center solutions, offering a comprehensive range of products and services to meet the diverse needs of our clients. With years of experience and a commitment to excellence, we have established ourselves as a trusted partner in the steel industry, delivering reliable solutions that optimize supply chain efficiency and meet...

More Tool Steel Service Centers

Tool Steel: Comprehensive Guide to Grades, Applications, and Selection

Tool steel is a highly specialized category of carbon and alloy steel formulated for superior hardness, abrasion resistance, toughness, and the ability to retain a cutting edge even under extreme working environments. Due to its unique properties and metallurgical composition, tool steel is essential for manufacturing tools and dies used in metalworking, machining, cutting, stamping, forming, and a range of high-precision industrial applications. Its exceptional performance makes it the material of choice for the fabrication of items that require long service life and endurance under stress, such as cutting tools, press dies, punches, and wear-resistant components.

What Is Tool Steel and Why Is It Important?

Tool steel refers to a family of steel alloys specifically designed to withstand the rigors of cutting, shaping, and forming other materials. When compared to conventional carbon steels or structural steels, tool steels are engineered with higher alloy content and greater control over microstructure, providing them with increased hardness, wear resistance, and toughness. These properties are critical in industries where tools must maintain sharp edges, structural integrity, and dimensional stability under high loads, repetitive impacts, and elevated temperatures.

Tool steel is frequently employed in metal drawing, blanking, stamping, slitting, forming, embossing, and extrusion operations. Its inherent hardness and durability enable it to cut, shape, and process other metals efficiently, making it indispensable for the manufacturing sector, automotive industries, aerospace, defense, construction, and even in household tools.

Tool Steel Grades and Their Significance

The American Iron and Steel Institute (AISI) classifies tool steel into standardized grades, which help manufacturers, engineers, and buyers select the right type for specific applications. These tool steel grades are denoted by letters and numbers, each corresponding to particular alloying elements, properties, and recommended use cases. The classification makes it easier to identify a tool steel’s composition, reactivity, hardenability, and performance characteristics.

- Grade A Tool Steel (Air-Hardening): Used primarily for cold working processes such as shearing, blanking, and forming where distortion during hardening must be minimized. It offers outstanding dimensional stability and moderate to high wear resistance.

- Grade D Tool Steel (High Carbon, High Chromium): Known for excellent abrasion resistance and used extensively in cold work applications like dies, punches, and cutting blades.

- Grade O Tool Steel (Oil-Hardening): Used for applications requiring good machinability, toughness, and ease of heat treatment. Common in knives, bushings, and cutting tools.

- Grade P Tool Steel (Plastic Mold Steel): Designed for making molds for plastics due to its high polishability, toughness, and dimensional stability.

- Grade H Tool Steel (Hot Work): Developed for applications involving exposure to elevated temperatures, such as die casting, forging, and extrusion dies, thanks to its thermal fatigue resistance.

- Grade S Tool Steel (Shock-Resisting): Engineered for tools subjected to high impact or shock loading, like chisels, punches, and rivet sets.

- Grade M Tool Steel (Molybdenum High-Speed): Commonly used in high-speed cutting tools, drills, and saws, offering exceptional hardness and red hardness at high operating speeds.

- Grade T Tool Steel (Tungsten High-Speed): Similar to M-grade but with tungsten as the primary alloying element, providing superior hot hardness and abrasion resistance.

- Grade W Tool Steel (Water-Hardening): The most cost-effective tool steel, suitable for low-temperature applications with simple shapes and minimal shock.

- Grade L Tool Steel (Low Alloy Special Purpose): Used for special applications requiring unique combinations of properties.

- Grade F Tool Steel (Forging): Designed for forging operations, offering good machinability and forging characteristics.

Each tool steel grade is characterized by high strength and moderate to high carbon content. This combination enables the steel to be heat treated for customized hardness, toughness, and resistance to wear, making it suitable for a wide array of industrial and commercial uses.

How Tool Steel Is Manufactured: Processes and Treatments

Tool steel production is a complex, multi-stage process that involves precise alloying, controlled melting, and carefully managed heat treatment procedures to achieve desired mechanical and physical properties. The steel is typically produced in an annealed condition, meaning it is heated to a specific temperature, formed into the desired shape, and then allowed to cool slowly to remove internal stresses and soften the structure for further processing.

Common Hardening and Heat Treatment Methods

- Air Hardening: In this process, tool steel is heated and then cooled in open air, resulting in uniform hardness and minimal distortion. Air-hardening tool steels (A-series) are preferred for applications where maintaining tight tolerances and dimensional stability after heat treatment is critical.

- Oil Hardening: Here, the steel is quenched in oil after heating, which promotes a balance between hardness and toughness. Oil-hardening tool steels (O-series) are widely used in the production of knives, dies, and cutting implements where machinability is important.

- Water Hardening: Tool steel is rapidly cooled in water, resulting in high hardness but also increased risk of cracking or warping. Water-hardening tool steels (W-series) are best suited for simple shapes and applications with lower risk of shock and stress.

In addition to these, other heat treatments such as tempering, annealing, and sub-zero treatments may be employed to further refine the microstructure, reduce brittleness, and enhance tool performance. The specific treatment chosen depends on the type of tool steel, its intended application, and the required balance of hardness, strength, and toughness.

Types of Tool Steel and Their Applications

Tool steels are commonly divided into three broad classes based on their intended operating environment and required performance attributes:

- Cold Work Tool Steel: Designed for use at lower temperatures, cold work tool steels (A, D, O, and S series) are employed in operations such as blanking, forming, shearing, stamping, and drawing. Their high wear resistance and ability to retain sharp edges make them ideal for manufacturing dies, punches, and cutting blades for sheet metal fabrication.

- Hot Work Tool Steel: These steels (H series) are engineered to withstand repeated exposure to elevated temperatures without losing strength or hardness. Hot work tool steels are essential in die casting, extrusion, forging, and other processes where the tool comes into direct contact with hot materials. Their resistance to thermal fatigue and ability to retain mechanical properties at high temperatures make them indispensable for heavy-duty industrial applications.

- High-Speed Tool Steel: Known for their ability to maintain hardness and cutting performance at temperatures exceeding 1,000°F (538°C), high-speed tool steels (M and T series) are the material of choice for high-speed cutting tools such as drills, end mills, saw blades, and taps. Their superior red hardness allows them to cut through tough alloys and hardened materials at high speeds without losing their edge.

Other specialty tool steels, such as shock-resistant (S series) and plastic mold (P series), are tailored for unique requirements such as impact resistance, polishability, and corrosion resistance.

Industries and Use Cases for Tool Steel

The versatility of tool steel makes it a foundational material across diverse sectors. Some key industries and applications include:

- Automotive Manufacturing: Used in the production of dies, molds, and cutting tools for manufacturing vehicle components, body panels, and drivetrain parts.

- Aerospace: Essential for fabricating high-precision components, turbine blades, aircraft frames, and maintenance tools that demand exceptional durability and dimensional accuracy.

- Construction: Utilized in the fabrication of concrete molds, forming tools, cutting edges for excavation equipment, and wear-resistant parts for heavy machinery.

- Tool and Die Making: The backbone of tool and die workshops, supporting the creation of stamping dies, forming dies, extrusion dies, and forging tools.

- Consumer Goods: Found in high-performance knives, scissors, hand tools, and even kitchen cutlery requiring sharpness and long-term reliability.

- Medical Devices: Used to manufacture surgical instruments and precision medical tools where corrosion resistance, edge retention, and sterilizability are paramount.

- Energy Sector: Applied in the production of specialized drilling, extraction, and processing tools where extreme conditions and wear resistance are critical.

Key Properties and Advantages of Tool Steel

Selecting the right tool steel involves understanding the performance attributes critical to your application. Tool steels are characterized by several unique properties that set them apart from standard carbon and alloy steels:

- Hardness: Tool steels can be heat treated to achieve very high hardness, enabling them to cut, shape, and form other materials with ease.

- Wear Resistance: High alloy content and optimized microstructure give tool steels exceptional resistance to abrasion, prolonging tool life and reducing replacement costs.

- Toughness: Many tool steels are engineered for impact resistance, reducing the risk of cracking or catastrophic failure under stress or shock loading.

- Red Hardness: High-speed and hot work tool steels retain their hardness and cutting ability even at elevated temperatures.

- Dimensional Stability: Properly alloyed tool steels minimize distortion during heat treatment, ensuring precise tolerances and consistent performance.

- Machinability: Certain tool steels are formulated for ease of machining, grinding, and finishing, enabling complex geometries and fine surface finishes.

- Corrosion Resistance: Some grades offer improved resistance to oxidation and corrosion for applications in humid or chemically aggressive environments.

How to Choose the Right Tool Steel for Your Application

Selecting the best tool steel for your needs requires careful consideration of several factors, including:

- Intended Use: What operations will the tool perform? (e.g., cutting, forming, stamping, molding, impact loading, high-speed machining)

- Operating Environment: Will the tool be exposed to high temperatures, corrosive substances, or repeated impact?

- Mechanical Requirements: Prioritize hardness, toughness, wear resistance, red hardness, or a combination based on application demands.

- Shape and Complexity: Complex or thin-walled tools may require grades with superior machinability and minimal distortion.

- Cost Considerations: Balance performance with budget, factoring in tool life, maintenance, and replacement costs.

- Heat Treatment Capabilities: Assess your facility’s ability to perform required heat treatments or post-processing steps.

For instance, if you’re planning to manufacture high-speed cutting tools, high-speed tool steels like M2 or T1 are optimal due to their red hardness and wear resistance. In contrast, for dies and punches subjected to impact or shock, shock-resistant tool steels such as S7 are better suited.

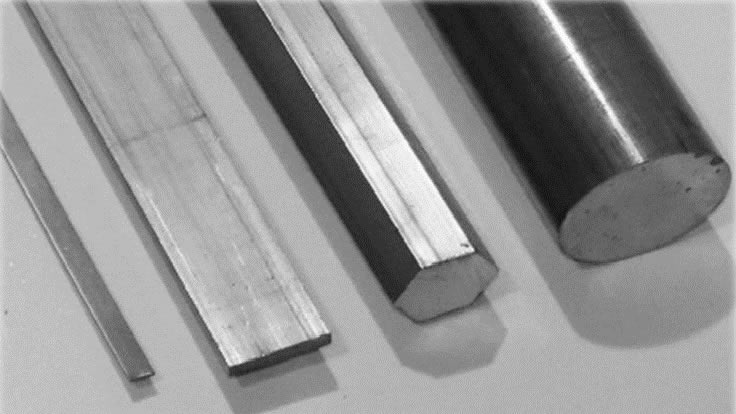

Common Forms and Finishes Available for Tool Steel

Tool steel is available in multiple forms and finishes to suit diverse manufacturing processes and end uses. Common supply forms include:

- Rounds and Bars: Used for machining into tools, dies, and shafts.

- Sheets and Plates: Ideal for die and mold bases, wear plates, and flat tools.

- Pre-Machined Blanks: Ready for final machining, reducing lead times.

- Precision Ground Stock: Tight tolerance bars and flats for high-precision toolmaking.

Surface finishes may range from as-rolled to precision ground or mirror-polished, depending on the end use and required surface quality.

Frequently Asked Questions About Tool Steel

What are the most commonly used tool steel grades?

Commonly used grades include A2 (air-hardening for general cold work), D2 (high carbon, high chromium for wear resistance), O1 (oil-hardening for ease of machining), H13 (hot work for die casting and extrusion), M2 (high-speed cutting tools), and S7 (shock-resistant for impact tools).

Can tool steel be welded?

Welding tool steel is possible, but it requires careful preparation, preheating, and post-weld heat treatment to prevent cracking and maintain desired properties. Consult material data sheets and experienced welders for best practices.

How is tool steel maintained and stored?

Tool steel should be stored in a dry, clean environment to prevent corrosion. Apply protective oils or coatings if necessary. Regular inspection, cleaning, and re-sharpening (for cutting tools) will maximize tool life.

What’s the difference between tool steel and high-speed steel?

High-speed steel (HSS) is a subset of tool steel designed to retain hardness at high temperatures, ideal for high-speed cutting tools. While all HSS is tool steel, not all tool steel qualifies as HSS. Other tool steels may prioritize toughness, shock resistance, or wear resistance over red hardness.

How does tool steel compare to stainless steel?

Tool steel is engineered for hardness, wear resistance, and toughness, while stainless steel is favored for its corrosion resistance. Some tool steels incorporate elements for both properties, but when corrosion resistance is critical, stainless steel may be preferred over tool steel.

Latest Trends and Innovations in Tool Steel

Advancements in metallurgy and materials engineering continue to drive innovation in tool steel technology. Manufacturers are developing new alloy combinations and powder metallurgy grades that offer improved performance, consistency, and sustainability. Key trends include:

- Powder Metallurgy Tool Steels: These steels offer superior uniformity, finer carbides, and improved wear resistance, enabling the production of highly complex and high-performance cutting and forming tools.

- Enhanced Heat Treatment Processes: New quenching, tempering, and sub-zero treatments provide even better control of hardness, toughness, and dimensional stability.

- Environmentally Friendly Alloys: Reduced use of hazardous elements and improved recyclability support sustainable manufacturing practices.

- Advanced Coatings: Physical vapor deposition (PVD) and chemical vapor deposition (CVD) coatings boost surface hardness, reduce friction, and extend tool life, especially in high-speed and high-temperature applications.

Conclusion: Why Tool Steel Remains Essential

Tool steel’s unmatched combination of hardness, toughness, wear resistance, and heat resistance makes it a cornerstone of modern manufacturing. Its adaptability to heat treatment and alloying allows for tailored solutions across the broadest range of industrial challenges. When selecting tool steel, it’s vital to weigh factors such as grade, application, operating environment, and cost to ensure optimal tool performance and longevity.

Whether you need dies for automotive manufacturing, high-speed cutting tools for machining, or precision molds for plastics, the right tool steel will deliver the reliability, durability, and efficiency that today’s competitive industries demand. By understanding the different grades, properties, and applications of tool steel, buyers and engineers can make informed decisions that drive productivity and ensure long-term value.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services