A General Overview of Steel Service Centers

Steel supply companies serve manufacturing customers through steel service center facilities. These plants specialize in the processing and finishing of commercial steels for a variety of industrial and manufacturing purposes. A steel service center typically purchases high volumes of steel as a wholesaler from mills. The company may store this material and re-sell it in smaller quantities to manufacturers or other steel processing enterprises. Read More…

Delta Steel is a leading provider of high-quality steel products, offering a comprehensive range of steel solutions to meet the diverse needs of our customers. With a commitment to excellence and reliability, we supply a wide variety of steel products for construction, manufacturing, infrastructure, and other industries.

At Delaware Valley Steel, we take pride in being one of the region’s most trusted steel service centers. We have built our reputation on precision, reliability, and the ability to deliver high-quality materials tailored to the unique needs of our customers.

At Grand Steel Products, Inc., we are a leading provider of steel service center solutions, offering a comprehensive range of products and services to meet the diverse needs of our clients. With years of experience and a commitment to excellence, we have established ourselves as a trusted partner in the steel industry, delivering reliable solutions that optimize supply chain efficiency and meet...

More Steel Service Centers Companies

Steel service centers are critical hubs within the metal supply chain, providing a broad range of steel processing, finishing, and distribution services to industries nationwide. These facilities frequently enhance their offerings by providing various steel finishing services, such as precision cutting, machining, drilling, and applying surface treatments including galvanizing, anodizing, and powder coating. The range of operations at each service center depends on the steel types requested by customers, the center’s specific technical capabilities, and industry demand. Steel service centers might produce and distribute high-strength beams, steel wire, steel plates, pipes, tubes, and other specialized steel products tailored to unique industrial requirements.

Steel Service Center Applications

Steel service centers have become indispensable across a diverse array of industries due to their ability to deliver both standard and custom steel solutions. Notably, the aluminized steel alloy sector and the recycling industry rely heavily on these centers for raw materials, fabricated components, and finishing services. However, nearly any manufacturer working with cladded, coated, or plated steel—whether sourced from cold-rolled or hot-rolled processes—can benefit from the expertise and efficiency of specialized steel service centers.

Are you a small manufacturer seeking specific steel grades or custom metal fabrication? Steel service centers often serve as one-stop shops, investing in advanced production capabilities tailored to particular finishing processes and industry standards. Their inventory typically includes a variety of steel with precise alloy compositions, such as carbon steel, stainless steel, tool steel, and high-strength low-alloy (HSLA) variants. As steel wholesalers, these facilities can cut and resell the metal in smaller, manageable quantities, allowing customers from automotive, construction, energy, and manufacturing sectors to access quality steel with desired properties and certifications.

Additionally, specialized service centers offer a vast range of processed commercial steels and metal products, including galvanized steel, cold-rolled steel, structural steel tubing, spring steel, heavy steel plates, aluminum-plated steel, rectangular and square tubing, and other finished metal forms. Some centers even provide precision steel sheets that have undergone advanced stretch leveling or temper passing, enabling purchasers to fabricate metal parts without the need for costly, in-house processing equipment. In North America, certain steel service centers serve niche markets by supplying finished steel bent to precise angles or plates treated to highly specific customer specifications. Occasionally, these centers also sell semi-finished or raw materials to other service centers for further processing, supporting a collaborative and efficient supply network.

Products Produced by Steel Service Centers

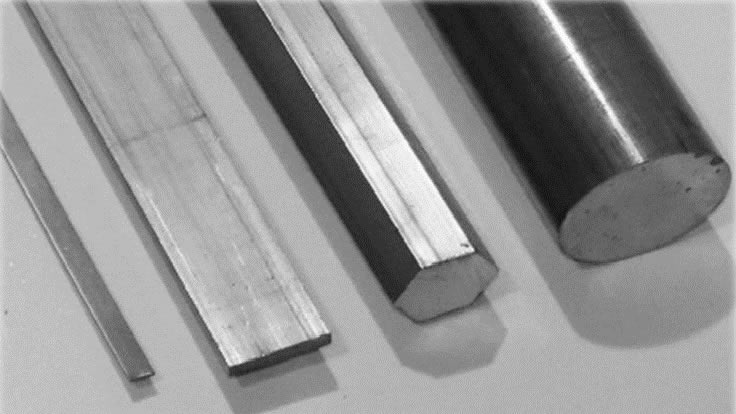

What types of steel products can you source from a steel service center? The variety is immense. Steel service centers offer a diverse range of products tailored for demanding applications. For instance, if a center has hot roll steel capabilities, it can temper and quench steel to create high-strength materials vital for automotive frames, aerospace components, structural beams, and heavy machinery. When a center heats hot roll steel above the recrystallization temperature, it gains the flexibility to apply surface treatments like pickling, oiling, or galvanizing to improve corrosion resistance and surface finish. Hot rolled steel is commonly used to produce plates, bars, and large sections, though it typically has lower structural integrity compared to cold rolled steel, which is favored for applications requiring tight tolerances and smooth surfaces.

Service centers equipped with blast furnace or electric arc furnace capabilities can also add specific alloying elements—such as chromium, nickel, or molybdenum—to molten steel, creating custom alloy steels for specialized requirements including resistance to wear, heat, or corrosion. Further, these facilities offer value-added services like slitting, blanking, laser cutting, plasma cutting, and waterjet cutting, all of which enable precise manufacturing of parts and assemblies. The ability to provide finished or semi-finished steel products—ranging from coils, sheets, and plates to beams, channels, and custom profiles—makes steel service centers essential partners for manufacturers in every sector.

Most steel service centers focus on cold rolled steel, offering critical processing services that would otherwise be labor-intensive or technologically complex for manufacturers to perform in-house. These centers often perform cold working operations, such as drawing, stamping, or rolling, that require stainless steel or other alloys to meet precise dimensional and mechanical standards. By shearing, bending, or cutting sheet metal to customer specifications, steel service centers enable more efficient and cost-effective metal parts production. The wide array of metal service operations available—including leveling, edge trimming, deburring, and coating—allows these facilities to cater to specialized steel retail markets and meet evolving industry demands for quality and customization, including plating or pressing steel into sheets as needed.

The History of Steel Service Centers

Steel service centers have a rich and dynamic history, serving as a backbone of the North American steel distribution network for over a century. The Metals Service Center Institute, a nonprofit trade association representing these centers, boasts a history of more than 100 years and plays a key role in advancing the interests and capabilities of the industry. Today, a large number of small, privately owned service centers dominate the marketplace, with some operating multiple facilities across the United States, Canada, and other countries, offering both regional and global reach.

The roots of steel service centers in the United States can be traced back to the early colonial period, when they were known as Iron Mongers and primarily facilitated the distribution of wrought iron and steel goods. At that time, only about 10% of steel products were processed through service centers. With the dawn of industrialization and the expansion of the railroad, automotive, and construction industries, the need for specialized steel processing and distribution grew rapidly. Today, approximately 30% of industrial steel products and 45% of specialty steel products are handled by these centers, reflecting their vital role in enabling efficient and flexible supply chains.

Steel production gained major industrial significance in the United States during the latter half of the 19th century, especially as new technologies like the Bessemer process and open hearth furnaces revolutionized steelmaking. From 1870 to 1913, steel production in the USA grew at an impressive rate of 7% per year, fueling the rise of large integrated steel mills and, subsequently, the need for independent service centers. The industry saw significant consolidation around the turn of the century, with US Steel acquiring Carnegie Steel, Federal Steel, and several major finishing firms. Antitrust actions by the federal government eventually dismantled this monopoly, paving the way for a vibrant landscape of smaller companies to enter the service center market.

By 1930, three major steel producers—US Steel, Bethlehem Steel, and Republic Steel—dominated the North American steel mill market. Nevertheless, a growing number of service center companies fostered competition in the wholesale sector by processing steel into products like wire, tubing, plate, and I-beams. This trend of diverse product offerings and services continues to shape the domestic steel and ferrous alloy markets today, supporting innovation and economic growth across countless industries.

Materials Processed at Steel Service Centers

What metals and alloys do steel service centers handle? Modern steel service centers process a wide variety of ferrous and non-ferrous metals to address the needs of multiple industries. While the primary focus remains on steel—including carbon steel, stainless steel, and alloy steel—many centers also process other metal alloys such as aluminum, copper, brass, and nickel alloys. For example, carbon steel coated in molten aluminum becomes cold-rolled aluminized steel, a versatile material in high demand for housewares, appliances, automotive heat shields, and consumer goods due to its excellent corrosion resistance and formability. Many steel service centers currently process and distribute these advanced cold-rolled products.

Steel service centers that focus on recycling and sustainability manage a wide range of scrap metals and metal alloys, offering environmentally responsible solutions for sourcing and processing raw materials. These facilities often perform secondary operations such as sorting, cleaning, shredding, and melting scrap metal to produce new steel products, supporting circular economy initiatives. Occasionally, centers plate metal surfaces with zinc, tin, or nickel to fulfill custom orders and enhance product performance. Worldwide, these steel service centers frequently work with various metals and may offer products such as stainless steel, carbon steel, iron, copper, nickel plate, aluminum plate, and custom alloy plates to meet the growing demands of industries from electronics to infrastructure.

A Detailed Examination of Steel Service Centers

Curious about how a steel service center operates? A typical steel service center functions by acquiring large quantities of raw or semi-finished steel from steel mills or scrap yards, storing this material in climate-controlled or secure warehouses, and then processing it as needed to fulfill custom orders. This operation typically involves three main steps:

Purchasing Operations

Steel service centers aim to acquire steel at competitive prices from steel mills, foundries, or other suppliers. They may establish contracts with specific producers or leverage spot market purchases, securing steel with precise alloys or alloy percentages to achieve high-strength, corrosion-resistant, or formable products. Best-in-class centers negotiate favorable terms based on market trends, inventory turnover, and customer demand forecasts, ensuring a steady supply of raw materials for manufacturing partners.

Storage Operations

Service centers are equipped with advanced material handling systems, cranes, racking, and transport vehicles to efficiently store and deliver raw or processed steel. This capability allows them to buy large volumes of steel when prices are low and maintain inventory to meet fluctuating customer demand, reducing lead times and supply chain risks. Inventory management systems and just-in-time (JIT) delivery strategies are often employed to optimize storage and minimize capital costs associated with holding excess stock.

Finishing Operations

Service centers often provide a wide array of steel finishing services. This may involve cutting steel into specified lengths, weights, or dimensions to meet custom orders. Services might include shearing carbon or stainless steel for manufacturers, cold rolling metal to produce sheets in desired sizes, or applying protective metal coatings such as galvanizing, painting, or passivation to meet specific customer requirements. Additional value-added services may include forming, bending, stamping, slitting, edge conditioning, and heat treating. These capabilities are essential for delivering ready-to-use steel products that meet stringent industry standards and end-use applications.

Establishing a service center involves navigating complex design considerations and adhering to relevant industry regulations. In North America, stringent environmental, labor, health, and safety laws impact metal processing operations. Factors such as economic considerations, inventory types, technological capabilities, quality control processes, and skilled personnel resources all play a critical role in successful service center management, ensuring compliance and operational excellence.

Service center operations offer diverse customization options, catering to various niche markets. These centers provide tailored steel products, including those made from specific alloys, advanced high-strength steels, or fabricated in unique dimensions and shapes, serving regional, national, and international customers in industries like automotive, energy, construction, shipbuilding, and industrial equipment.

Machinery Used at a Steel Service Center

The machinery and equipment used to finish and process steel at service centers can vary widely depending on the products and services offered by each facility. Different production processes enable the creation of specially finished steels, and steel service centers often invest in high-capacity, advanced machinery to serve specific market niches and customer requirements.

Typically, these centers provide warehouse shipping, processing, and distribution services for the extended storage and movement of steel. They also need to be equipped for shearing, slitting, and cutting steel to precise lengths and shapes for custom orders. Some centers handle steel transportation with their own fleet of trucks or partner with logistics companies for regional and national distribution, ensuring timely delivery to customers.

Companies that engage in extensive cold working may invest in heavy machinery tailored to process the specific types of steel and metal alloys in their inventory. Such facilities often use hydraulic presses, plate rolls, brake presses, CNC cutting machines, laser cutters, plasma torches, and waterjet systems to shape steel into sheets, bars, tubes, and complex profiles. Many centers also offer value-added services like electroplating, powder coating, and non-destructive testing to ensure product quality and performance. Robust quality assurance and testing equipment—such as hardness testers, spectrometers, and ultrasonic flaw detectors—are often part of the operation, ensuring that steel products meet industry certifications and customer expectations.

Variations on Steel Service Centers

Certain steel service centers specialize not in specific metals like steel, aluminum, copper, or alloys, but rather in serving particular industries or end-use applications. Their clientele often includes companies in highly specialized markets, such as plumbing supply, oil and gas drilling pipeline firms, aerospace contractors, or renewable energy developers. These centers offer metal products and services tailored to the operational and compliance needs of the industries they serve, providing expertise in areas such as pressure vessel fabrication, structural steel for bridges, or corrosion-resistant alloys for marine environments.

Some service centers extend their reach by offering engineering support, supply chain consulting, and vendor-managed inventory (VMI) programs, helping customers streamline their procurement process and reduce operational complexity. By focusing on industry-specific requirements—such as ASTM, ASME, or ISO standards—these centers provide added value beyond raw materials, fostering long-term partnerships with customers in sectors like transportation, defense, construction, mining, and infrastructure development.

Some Advantages of Using Steel Service Centers

Customers who utilize steel service centers gain several significant advantages, making these facilities a strategic choice for companies seeking reliability, flexibility, and value in their supply chain.

Firstly, they benefit from cost efficiencies by purchasing small or large volumes of specialized steel while still reaping the savings from economies of scale inherent in bulk procurement and processing handled by the service centers. These savings are often passed on to customers who typically order in smaller quantities, reducing overall material costs and improving profit margins.

Steel service centers are not just about steel supply—they also play a vital role in metal storage and logistics. This relieves manufacturers from the burden of investing in their own storage facilities, inventory management systems, and material handling equipment. Instead, they can rely on these centers for on-demand steel supply, saving valuable space, reducing storage costs, and improving cash flow by minimizing inventory on hand.

Many steel service centers specialize in specific types of steel, such as galvanized, spring, structural plate, tool steel, or stainless steel. This specialization allows manufacturers to source the exact materials they need, with the right mechanical properties, surface finishes, and certifications, without the expense or complexity of setting up their own finishing facilities or allocating resources for steel preparation. This access to expertise and inventory flexibility is especially valuable for small and mid-sized manufacturers, prototype developers, and custom fabricators.

The presence of diverse steel service centers enhances product diversity and fosters greater market competition by ensuring that companies of all sizes can access a range of finished steels, specialty alloys, and custom-fabricated products. This competitive environment drives innovation and quality improvements across the steel supply chain.

By offering custom shearing, cutting, and fabrication services, steel service centers also support small and mid-sized manufacturing operations. These centers can cut steel into precise shapes and sizes as required, perform secondary operations like drilling and tapping, and deliver ready-to-assemble parts, streamlining the manufacturing process and saving companies the cost and effort of cutting metal themselves. This end-to-end service accelerates time-to-market for new products and enables customers to focus on their core competencies.

Other advantages of partnering with a steel service center include improved lead times, reduced supply chain risks, access to technical support and material expertise, compliance with industry standards, and the ability to respond quickly to changing market demands. Whether you need just-in-time delivery, small-batch specialty alloys, or large-scale structural steel fabrication, steel service centers offer the capacity, flexibility, and service quality to meet your needs.

How to Select the Best Steel Service Center

How do you choose the right steel service center for your project or ongoing supply needs? Use this website to find a variety of steel supply companies and products, covering everything from standard sheet and plate to custom-fabricated components and value-added processing services. We provide contact information for numerous steel service centers, enabling you to compare capabilities, inventory, certifications, and industry experience. By starting here, your company can identify the best vendors and business partners based on location, service offerings, and technical expertise. Many suppliers specialize in specific market niches—such as automotive steel, energy sector alloys, or architectural fabrication—so depending on your manufacturing needs, you may choose to work with several steel supply service centers to optimize your supply chain.

When evaluating potential partners, consider factors such as:

- Product Range and Inventory: Does the center stock the steel types, grades, and forms you need? Do they offer specialty alloys, coatings, or custom fabrication?

- Processing Capabilities: Can the service center perform the required cutting, forming, machining, or finishing operations in-house?

- Certifications and Quality Assurance: Does the center comply with industry standards (ISO, ASTM, ASME) and offer traceability for materials?

- Lead Times and Delivery: What are average processing times and delivery schedules? Do they provide just-in-time (JIT) delivery or vendor-managed inventory (VMI) options?

- Technical Support and Customer Service: Are experienced engineers or metallurgists available to assist with material selection, application advice, or troubleshooting?

- Reputation and Experience: How long has the center been in business? Do they have a proven track record in your industry?

- Pricing and Terms: Are their prices competitive? What are their payment terms, order minimums, and contract flexibility?

By carefully assessing these criteria and leveraging the resources available on our website, you can confidently select the best steel service center partners for your business. Whether you’re searching for a local supplier for rapid turnaround or a national distributor for large-scale projects, the right service center can provide a critical competitive edge in quality, cost, and supply chain efficiency.

Ready to take the next step? Explore our directory or contact listed steel service centers to discuss your project requirements, request a quote, or schedule a facility tour. The expertise and resources of today’s leading steel service centers remain essential for manufacturers, fabricators, and builders seeking quality, reliability, and innovation in every steel solution.

What services do steel service centers provide?

Steel service centers offer a wide range of services including steel processing, finishing (cutting, machining, drilling), surface treatments like galvanizing and powder coating, and distribution of steel products tailored to customer requirements. Many also provide inventory management, storage, and just-in-time delivery.

What types of steel products can you source from a steel service center?

Steel service centers supply products such as beams, wires, plates, pipes, tubes, sheets, coils, bars, channels, and custom profiles. These can be hot rolled, cold rolled, galvanized, or coated, and produced to meet specific industry requirements and standards.

What industries rely on steel service centers?

Industries that rely heavily on steel service centers include automotive, construction, energy, manufacturing, aerospace, shipbuilding, infrastructure development, and recycling. These centers serve both standard and highly specialized market niches.

Which materials can be processed at steel service centers?

Modern steel service centers primarily process steel, including carbon, stainless, and alloy steels, but many also work with aluminum, copper, brass, nickel alloys, and other metals. Some also handle recycling and processing of scrap metals to support sustainability.

What advantages do steel service centers offer manufacturers?

Steel service centers provide cost efficiencies through bulk procurement, custom cutting and fabrication, access to specialized alloys, improved lead times, technical support, inventory management, and flexible supply options. This enables manufacturers to save on material costs, storage, and processing while maintaining product quality and customization.

What machinery is commonly used at steel service centers?

Steel service centers employ machinery such as hydraulic presses, plate rolls, brake presses, CNC cutters, laser and plasma cutting machines, waterjet systems, cranes, racking systems, and testing equipment for quality assurance and material handling.

How can I choose the best steel service center for my needs?

When selecting a steel service center, consider their range of products and inventory, processing capabilities, certifications, lead times, technical support, reputation, experience, and pricing. Comparing these factors can help you find partners that match your technical and logistical requirements.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

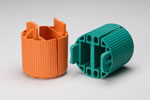

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services