They can be used as railings, in ladders, as poles and even as support rods in exercise equipment. They can be used to support floating wooden or plastic docks on rivers and lakes. Read More…

Delta Steel is a leading provider of high-quality steel products, offering a comprehensive range of steel solutions to meet the diverse needs of our customers. With a commitment to excellence and reliability, we supply a wide variety of steel products for construction, manufacturing, infrastructure, and other industries.

At Delaware Valley Steel, we take pride in being one of the region’s most trusted steel service centers. We have built our reputation on precision, reliability, and the ability to deliver high-quality materials tailored to the unique needs of our customers.

At Grand Steel Products, Inc., we are a leading provider of steel service center solutions, offering a comprehensive range of products and services to meet the diverse needs of our clients. With years of experience and a commitment to excellence, we have established ourselves as a trusted partner in the steel industry, delivering reliable solutions that optimize supply chain efficiency and meet...

More Steel Tubing Service Centers

Steel tubes can be used in plumbing and electrical wiring applications, they can be shaped into furniture and they can be used to make mechanical parts. Fences, gates, lawn and garden equipment, playground equipment, trailer safety equipment, flu tubes, automobiles, conveyors, flag poles and farm equipment can all involve steel tubes of some kind.

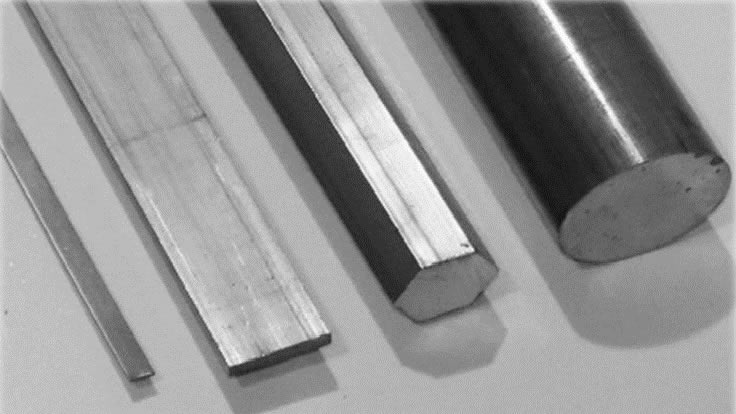

Steel tubing can be made to any specifications; shape, size and thickness are variable depending on the intended application of the tubing. Steel manufacturers can produce round, square, rectangular, oval or hexagonal tubing. An extensive variety of industries make use of tubing; these include the construction, automotive, electronics, shipbuilding, furniture, plumbing, aerospace and many other industries.

In addition to all of the different steel tubing shapes and sizes, steel tubing can be made to varying specifications of thickness, corrosion resistance, heat resistance, strength and other physical properties.

There are multiple types of steel tubing available. These include cold rolled steel tubing, galvanized steel tubing, hot rolled pickled and oiled steel tubing, electro-galvanized tubing, galvannealed steel tubing and several other varieties. Because of the wide variety of uses, each kind of steel tubing has its own unique attributes and ideal applications, and therefore each tube must meet tight specifications for its particular function.

CNC machining, flaring, reductions, welding and brazing are some of the processes that can be used to form steel tubing. Steel tubing can be made in many ways; a wide variety of industrial processes are capable of creating tube shapes. Steel tubing can be made by the extrusion process, which involves melting the steel and forcing it through a specially shaped tool, which is called a die.

Extrusion requires a stock of raw steel that can easily be melted and shaped. In some cases, such heat-intensive processes are not feasible for steel shaping. In such cases, steel tubing can be formed by cold forming processes. A cold forming process is any metal forming process that does not involve heating the metal above its recrystallization temperature. Such processes decrease the risk of oxidation and can be less expensive than hot processes.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services