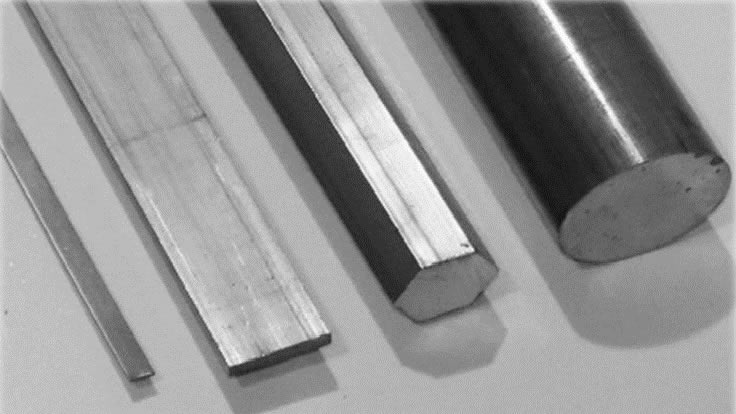

Hot rolled steel that has undergone additional processing at room temperature to enhance its mechanical and dimensional properties is known as cold rolled steel. During this transformation, hot rolled steel is cooled to room temperature and run through a series of rollers. These rollers form the now cold rolled steel, providing the material with tighter dimensional tolerances and other favorable qualities. For example, strain hardening, also known as plastic deformation of the material, occurs as a sheet of metal is passed between two rollers. The steel is given greater strength levels because of this flattening without heat and producing cold rolled steel products. Read More…

Delta Steel is a leading provider of high-quality steel products, offering a comprehensive range of steel solutions to meet the diverse needs of our customers. With a commitment to excellence and reliability, we supply a wide variety of steel products for construction, manufacturing, infrastructure, and other industries.

At Delaware Valley Steel, we take pride in being one of the region’s most trusted steel service centers. We have built our reputation on precision, reliability, and the ability to deliver high-quality materials tailored to the unique needs of our customers.

At Grand Steel Products, Inc., we are a leading provider of steel service center solutions, offering a comprehensive range of products and services to meet the diverse needs of our clients. With years of experience and a commitment to excellence, we have established ourselves as a trusted partner in the steel industry, delivering reliable solutions that optimize supply chain efficiency and meet...

More Cold Rolled Steel Service Centers

The Uses of Cold Rolled Steel

Automobile parts, building supplies, appliances, furniture, computer cabinet hardware, minor appliance parts, and other components are among the uses for cold rolled steel. In addition, cold rolled steel of commercial quality is frequently employed in light-duty construction applications. For example, commercial quality cold rolled steel is frequently used to manufacture door frames, stairway parts, and other relatively tiny steel construction elements.

Hand Tools

Cold rolled steel is great for hand and machine tools like drill bits and dies. The high material hardness of this steel makes it resistant to flattening and deformation. Additionally, it possesses great toughness, superior breaking resistance, and resistance to erosion and abrasion.

Building and Construction Sector

Cold rolled steel has been highly sought after in construction, particularly for framing uses. A cold rolled steel frame is stronger and lighter than competing options. In recent years, multi-housing structures, including dorms, hotels, and assisted living facilities, have favored cold formed steel framing.

Household

The use of cold rolled steel in furniture and appliances for the home is appropriate.

Cold Rolled Steel Light Fixtures

Lighting fixtures made of various materials are likely to be seen when entering a store selling home furnishings. This results from differences in visual appeal; a light fixture made of cold rolled steel will look different than one made of aluminum, copper, or brass. But differences go beyond appearance. Because of its exceptional qualities, such as high-tensile and high-yield strength, cold rolled steel is frequently used to create lighting fixtures in applications demanding high precision. Meanwhile, since it works well with various surface finishes, colors, and designs, cold rolled steel is a fantastic choice for interior design.

Household Uses of Cold Rolled Steel

Finding a home without some cold rolled steel isn't easy, even when it isn't used in interior design. Nearly all parts and components of household appliances are made of this sturdy substance. Appliances made of cold rolled steel include microwaves, washers, and dryers. In addition, it can be found in computer hardware, lawnmowers, and water heaters.

Production Methods for Cold Rolled Steel

Cold rolled steel can be formed using various techniques, such as bending, hemming, drawing, stretching, flanging, and draw or stretch shaping. However, the risk of oxidation always exists when heat-treating steel is eliminated by the cold rolling method's lack of heat utilization. Therefore, cold rolled steel is frequently used in products that need the incorporation of robust steel shapes and have a smooth surface texture. The method is carried out at or near room temperature. Typically, oil is applied to the steel before shaping.

Quality Levels of Cold Rolled Steel Types

Products made of cold rolled steel come in three different quality levels. First, there is commercial quality, which is primarily utilized when working with hollow metal. The second variety, referred to as drawing quality, is more ductile. Metal drawing, a method that employs tensional forces to draw metal, produces high-quality cold rolled steel (this increases its flexibility). The third quality, physical quality, refers to further processed commercial steel.

Advantages of Cold Rolled Steel

Cold rolled steel can be recycled entirely. It readily accepts several surface treatments and is renowned for maintaining tight tolerance. Due to strain hardening, cold rolled steel has approximately 20% higher strength than hot-rolled steel. In addition, the steel does not shrink as it cools, unlike in the hot-rolled method, because the operation is done at ambient temperature; this is why cold roll steel is preferred in home appliances, especially those with fluctuating temperatures.

One of the most significant advantages of the cold rolling process is eliminating oxidation concerns. Despite having a smaller form range than hot-rolled steel, cold rolled steel has its advantages. We’ll discuss a couple of these advantages below.

Gained Strength

Cold rolled steel is substantially stronger than hot-rolled steel. Due to strain hardening, the steel gets stronger as the rollers compress it at room temperature.

Increased Surface Quality

The surface finish of cold rolled steel is also better. Compared to hot-rolled steel, it is smoother and has fewer surface defects. These qualities enhance the aesthetics of cold rolled steel while also making it a better material for specific uses, such as the construction of bridges.

Choosing the Proper Cold Rolled Steel Manufacturer

To make sure you have the most productive outcome when purchasing cold-rolled steel from a cold-rolled steel manufacturer, it is important to compare at least 4 or 5 companies using our list of cold-rolled steel manufacturers. Each cold rolled steel manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each cold rolled steel company website using our proprietary website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple cold rolled steel companies with the same message.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services