The Role of Steel Service Centers in Modern Industry

Steel service centers are indispensable in modern supply chains, serving as critical links between steel mills and various industries, including automotive, construction, manufacturing, and infrastructure. These centers play a unique role in bridging the gap between raw material production and the specialized needs of end-users. By stocking, processing, and distributing steel products, service centers enable faster and more efficient access to essential materials.

What Steel Service Centers Offer

Steel service centers provide a broad range of services that go beyond simple warehousing and distribution. They often cut, slit, level, and coat steel to meet specific client requirements, allowing manufacturers to receive steel that’s already prepared for their production lines. This customization reduces waste, improves efficiency, and cuts down on production time, making these centers highly valuable partners for manufacturers who rely on tailored steel products.

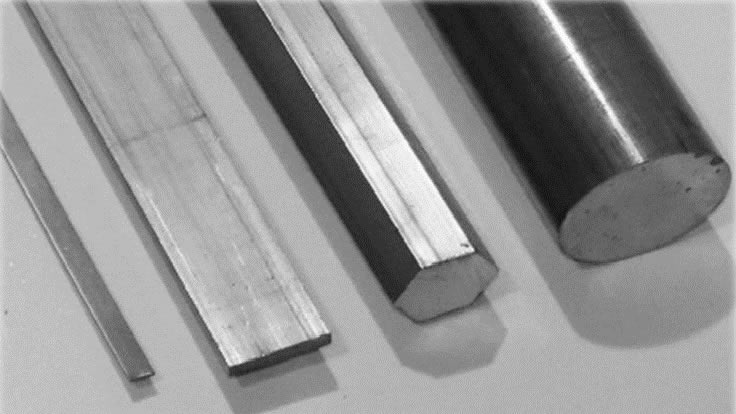

The Types of Steel Products Available

Most steel service centers offer a wide variety of products, including flat-rolled steel, bars, tubes, sheets, and coils. These are often produced in various grades and finishes to match the needs of different applications. For example, high-strength steel may be provided for automotive and construction applications, while more specialized types of stainless steel are often used in industries that require resistance to corrosion, such as food processing or medical manufacturing.

Improving Supply Chain Efficiency

One of the most significant benefits provided by steel service centers is their role in enhancing supply chain efficiency. By keeping inventory in strategic locations and providing quick turnaround times, they reduce the need for companies to hold large steel inventories themselves. Many centers also operate near major industrial hubs, allowing them to respond to clients’ needs rapidly and efficiently, and improving overall supply chain responsiveness.

Embracing Eco-Friendly Practices

With sustainability becoming increasingly important, many steel service centers have embraced eco-friendly practices, including recycling, reducing waste, and improving energy efficiency. Centers are investing in environmentally responsible processing techniques and materials, helping to lower the overall environmental impact of the steel industry. These practices not only benefit the environment but also appeal to clients looking to make sustainable choices.

Looking Toward the Future

As industries continue to evolve, steel service centers are adapting by integrating new technologies, such as digital inventory management systems and automation. These innovations allow them to provide real-time inventory data, streamlined ordering processes, and even predictive services that anticipate client needs based on historical data.

Ultimately, steel service centers are set to remain critical components of the supply chain. Their role in reducing costs, improving material readiness, and advancing sustainable practices will likely grow in importance as industries continue to prioritize efficiency and environmental responsibility.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services