Steel manufacturers play a vital role in powering various industries with their production of one of the most versatile and essential materials in the world: steel. Steel is a strong and durable alloy that finds application in a wide range of sectors, from construction and infrastructure to automotive and aerospace industries. Read More…

Delta Steel is a leading provider of high-quality steel products, offering a comprehensive range of steel solutions to meet the diverse needs of our customers. With a commitment to excellence and reliability, we supply a wide variety of steel products for construction, manufacturing, infrastructure, and other industries.

At Delaware Valley Steel, we take pride in being one of the region’s most trusted steel service centers. We have built our reputation on precision, reliability, and the ability to deliver high-quality materials tailored to the unique needs of our customers.

At Grand Steel Products, Inc., we are a leading provider of steel service center solutions, offering a comprehensive range of products and services to meet the diverse needs of our clients. With years of experience and a commitment to excellence, we have established ourselves as a trusted partner in the steel industry, delivering reliable solutions that optimize supply chain efficiency and meet...

More Steel Service Centers

Types of Steel Produced by Steel Manufacturers

Steel manufacturers produce several types of steel to cater to the specific needs of different industries. Carbon steel, which is predominantly composed of iron and carbon, finds extensive application in construction and infrastructure projects, thanks to its strength and affordability. Alloy steel, on the other hand, is created by adding various alloying elements like chromium, nickel, and molybdenum to enhance specific properties. This type of steel is widely used in the automotive and aerospace industries, where high strength, durability, and heat resistance are required. Stainless steel, known for its corrosion resistance, meanwhile, is utilized in a vast array of applications, including kitchenware, medical equipment, and construction. Furthermore, tool steel, with its high hardness and wear resistance, is indispensable in manufacturing tools and dies. Lastly, electrical steel, designed with low magnetic core losses, is essential in the production of electrical transformers and motors.

Processes Used by Steel Manufacturers

Steel manufacturers employ various processes to produce steel, each suited to different requirements. The basic oxygen furnace (BOF) process is commonly used for mass production of carbon steel. It involves injecting oxygen into a vessel containing molten iron, which burns off impurities and results in the production of high-quality steel. Electric arc furnace (EAF) technology, meanwhile, is employed for recycling scrap metal and producing alloy steel. By using electric arcs to melt the scrap, this process reduces waste and provides an environmentally friendly option for steel production. Continuous casting is another significant process used by steel manufacturers, allowing the production of steel slabs, billets, and blooms in a continuous manner.

Regardless of the production method used secondary refining processes, such as ladle refining, vacuum degassing, and ladle metallurgy, are employed by steel manufacturers using both the basic oxygen furnace (BOF) and electric arc furnace (EAF) methods to remove impurities, adjust composition, and improve the quality of the steel. Similar refining processes are also applied during continuous casting to remove impurities, adjust composition, and enhance the quality of the steel products, including slabs, billets, and blooms.

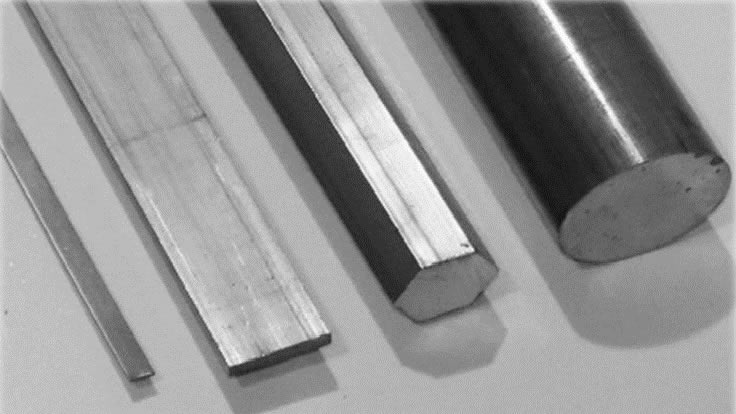

Forms of Steel Produced by Steel Manufacturers

Steel is produced in various forms to meet the diverse needs of different industries. Flat steel, including sheets, plates, and strips, finds application in construction materials, automotive parts, and household appliances. Long steel, such as bars, rods, and structural sections, is widely used in construction, infrastructure projects, and manufacturing. Tubular steel, which includes pipes and tubes, serves essential roles in pipelines, the oil and gas industry, and construction projects. Specialty steel, tailored to meet specific performance requirements, is employed in high-performance applications such as aerospace components and power generation equipment.

Considerations Regarding Steel Manufacturers

While steel is a crucial material for many industries, there are considerations to account for associated with its production. The environmental impact of steel manufacturing, including deforestation for iron ore extraction and the release of greenhouse gasses during production, poses significant challenges. Carbon emissions are a notable concern, as steel production accounts for a substantial portion of global CO2 emissions. Additionally, the resource intensity required for steel production, including vast amounts of energy and water, presents sustainability challenges that must be addressed.

Positive Efforts of Steel Manufacturers

Recognizing the need for sustainability and environmental responsibility, steel manufacturers have taken significant steps to combat these considerations. To begin with, the industry has embraced cleaner production technologies and processes, such as using electric arc furnaces for recycling scrap metal and reducing energy consumption. Increased utilization of recycled materials in steel production has also become a priority, reducing the dependence on virgin resources and minimizing environmental impact. Furthermore, steel manufacturers have implemented energy efficiency initiatives to optimize their operations and reduce carbon emissions. Research and development efforts are also underway due to the efforts of steel manufacturers in order to explore low-carbon steel production methods, including the use of renewable energy sources and carbon capture technologies. By actively addressing these considerations, steel manufacturers are working towards a more sustainable and responsible future.

Benefits Provided by Steel Manufacturers

Steel manufacturers offer numerous benefits that contribute to the success and growth of industries worldwide. One of the primary advantages of steel is its exceptional strength and durability. Steel structures and components can withstand heavy loads, extreme weather conditions, and the test of time, ensuring safety and longevity in various applications. Moreover, steel's versatility allows it to be customized and shaped according to specific requirements, making it suitable for diverse industries and applications. Another key benefit of steel is its recyclability and sustainability. Steel is one of the most recycled materials globally, with a high recycling rate that helps conserve resources and reduce waste. By incorporating recycled steel into production processes, manufacturers contribute to a circular economy and minimize the environmental impact associated with steel production. Additionally, steel's long lifespan and recyclability ensure that it remains a sustainable choice for industries. Furthermore, steel manufacturers play a crucial role in driving economic development. The steel industry creates employment opportunities, fosters innovation, and contributes to national and regional economies. From job creation in steel plants to downstream industries that rely on steel products, the economic ripple effect of steel manufacturing is significant.

Applications of Steel Manufacturers

Steel manufacturers cater to a diverse range of industries, offering their invaluable contributions through the applications of steel. In the construction and infrastructure sector, steel is the backbone of iconic structures, towering skyscrapers, and robust bridges. Its exceptional strength, durability, and flexibility make it the material of choice for supporting structures, reinforcing concrete, and creating architectural marvels that withstand the test of time. Furthermore, steel is extensively used in the automotive industry, where its high strength, formability, and crashworthiness contribute to the manufacturing of car bodies, chassis, and various components. The aerospace industry relies on steel for its ability to meet stringent requirements, such as lightweight construction, high temperature resistance, and structural integrity, making it ideal for aircraft components, engine parts, and structural elements.

Expanding on specific applications, steel manufacturers also play a crucial role in producing steel for transformers and motors. Electrical steel, a specialized form of steel, is designed with low magnetic core losses, making it perfect for the efficient operation of transformers and motors. Electrical transformers are vital components of power distribution networks, responsible for stepping up or down voltages. Steel manufacturers provide the necessary electrical steel laminations that form the core of transformers, enabling the efficient transmission and distribution of electricity. Similarly, electric motors, used in a wide range of applications, rely on steel laminations to construct the stator and rotor cores. Steel manufacturers ensure the production of high-quality electrical steel, facilitating the smooth and reliable operation of transformers and motors across industries.

In addition to these critical applications, steel manufacturers supply the household appliance industry with the materials needed for a multitude of products. Stainless steel, with its corrosion resistance, hygiene properties, and aesthetic appeal, is widely used in the production of household appliances. From refrigerators and dishwashers to ovens and washing machines, steel manufacturers provide the necessary stainless steel components that ensure durability, longevity, and sleek design in these essential household appliances. Moreover, steel's thermal conductivity allows for efficient heat transfer in cooking appliances, enhancing performance and precision. Finally, steel plays a vital role in the oil and gas industry, being extensively utilized for pipelines, offshore platforms, and other critical infrastructure due to its strength, corrosion resistance, and ability to withstand harsh operating conditions.

Choosing the Correct Steel Manufacturer

To ensure you have the most productive outcome when purchasing steel from a steel manufacturer, it is important to compare several companies using our directory of steel manufacturers. Each steel manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or to request a quote. Review each steel manufacturer business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple steel manufacturers with the same form.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services