The term “spring steel” describes a class of low alloy, medium-to-high carbon steel products with outstanding yield strength. Yield strength is the ability of a material to withstand severe bending and return to its original shape without deforming. Silicone is often present in spring steel stock alloys. These alloys are hardened, and cold rolled to increase yield strength. Spring steel is often cold drawn as wire or punched from flat stock to produce the final product. Saw blades, tape measures, helical springs, and car suspension parts are typical applications. Read More…

Delta Steel is a leading provider of high-quality steel products, offering a comprehensive range of steel solutions to meet the diverse needs of our customers. With a commitment to excellence and reliability, we supply a wide variety of steel products for construction, manufacturing, infrastructure, and other industries.

At Delaware Valley Steel, we take pride in being one of the region’s most trusted steel service centers. We have built our reputation on precision, reliability, and the ability to deliver high-quality materials tailored to the unique needs of our customers.

At Grand Steel Products, Inc., we are a leading provider of steel service center solutions, offering a comprehensive range of products and services to meet the diverse needs of our clients. With years of experience and a commitment to excellence, we have established ourselves as a trusted partner in the steel industry, delivering reliable solutions that optimize supply chain efficiency and meet...

More Spring Steel Service Centers

Spring Steel: Properties, Applications, Benefits, and Supplier Selection Guide

Spring steel is a specialized family of medium to high carbon steel alloys, renowned for their exceptional elasticity, resilience, and high yield strength. The defining property of spring steel alloys lies in their ability to withstand significant twisting, bending, or compressive forces without distorting, cracking, or losing their original shape. Owing to their unique metallurgical composition, spring steels are engineered to endure continuous cycles of bending, compression, extension, and torsion, making them indispensable across a wide range of demanding industrial and commercial applications.

Typically, spring steel alloys feature a medium-to-high carbon content, with manganese and silicon added as key alloying elements. The inclusion of silicon, in particular, substantially increases the alloy’s yield strength, imparting the material with the flexibility and toughness required for repeated stress cycles. The precise balance of alloying ingredients is what enables these steels to perform reliably in high-stress environments, where both durability and fatigue resistance are critical to performance.

What Makes Spring Steel Unique?

Spring steel distinguishes itself from other steel grades through its robust combination of strength, flexibility, and resistance to deformation. Unlike standard carbon or alloy steels, spring steel can be bent, twisted, or compressed many times over without permanent set or breakage, making it ideal for components that must return to their original form after deflection.

Another essential characteristic is the way spring steel is processed. To preserve and enhance its yield strength and elasticity, spring steel stock is typically worked cold after casting. This means that, instead of being subjected to high temperatures during manufacturing (which could negatively affect its mechanical properties), the alloy is cold drawn or cold rolled into flat sheets or wire. Most spring steel products are then further shaped—coiled, punched, or formed—according to their end-use requirements.

It is important to note that spring steel components generally cannot be welded without a subsequent retempering process, as welding can compromise the hardened structure. Instead, the alloys are often hardened to Rockwell C values between 42 and 60, followed by cold working to achieve the desired geometry and surface finish. In some applications, intricate parts are crafted from soft, annealed stock and then hardened after forming for optimal mechanical performance.

Comprehensive Applications of Spring Steel

Why is spring steel chosen for so many challenging engineering projects? The answer lies in its superior combination of strength, elasticity, and resistance to shock and fatigue failure. The addition of silicon during alloying imparts the ability to absorb impacts and withstand asymmetrical bending, allowing the metal to stretch and flex without sustaining permanent deformation.

Key Spring Steel Use Cases

- Mechanical Springs: The most common application, where spring steel’s high yield strength and elasticity are pivotal for storing and releasing mechanical energy in compression, extension, or torsion springs.

- Automotive Components: Used extensively in suspension systems, leaf springs, coil springs, valve springs, and stabilizer bars for enhanced durability and fatigue resistance.

- Cutting Tools and Blades: High carbon spring steel is favored in the manufacture of knives, saw blades, small files, and cutting edges, thanks to its hardness and ability to maintain a sharp edge.

- Clips, Fasteners, and Retainers: The material’s flexibility and memory enable the reliable performance of snap rings, circlips, clamps, and retaining pins.

- Precision Instruments: Spring steel finds use in measuring tapes, rules, and steel tapes, where repeated flexing is required without loss of accuracy.

- Plastic Injection Molding: Used for making molds, due to its ability to maintain dimensional stability under repeated cycles.

- Electrical Contacts and Relays: Its conductivity and resilience make it suitable for various precision electrical components.

- Musical Instruments: Certain types of music wire, such as piano and guitar strings, are crafted from spring steel for their tonal quality and durability.

- Medical Devices: Blue-tempered spring steel is used for making blades, surgical tools, and certain medical instruments due to its hardness and corrosion resistance.

Whether you’re seeking material for robust mechanical assemblies, high-performance automotive parts, precision instruments, or specialized cutting tools, spring steel offers a versatile solution that balances flexibility, hardness, and resistance to wear and fatigue.

Industry-Specific Applications

Spring steel’s unique properties make it a material of choice across multiple industries:

- Automotive Industry: For critical parts like suspension springs, clutch plates, and anti-roll bars, where high cyclic loading is standard.

- Aerospace Sector: In landing gear springs, control cables, and safety-critical fasteners requiring consistent performance under extreme conditions.

- Industrial Manufacturing: For machine parts, conveyor belt mechanisms, and vibration-damping elements that must endure repeated motion and shock.

- Construction and Engineering: Used in load-bearing supports, reinforcement elements, and building hardware.

- Consumer Goods: In household tools, hand tools, scissors, and clipboards where resilience and form retention are required.

- Medical and Surgical: High-grade spring steel is integral to certain surgical blades, retractor springs, and other precision medical equipment.

Manufacturing Process: How Is Spring Steel Made?

Understanding the manufacturing process for spring steel is crucial for engineers, buyers, and manufacturers seeking to optimize material selection and performance. The properties that define each type of spring steel are directly influenced by the alloying elements, heat treatment, and mechanical working techniques used during production.

Alloying and Melting

Spring steel production begins with careful selection and blending of raw materials. The process typically starts by melting high-grade iron ore with controlled amounts of carbon (C), manganese (Mn), silicon (Si), and sometimes chromium (Cr), vanadium (V), nickel (Ni), or molybdenum (Mo), depending on the grade. These elements are chosen to impart specific mechanical properties—such as tensile strength, ductility, and corrosion resistance—tailored to the intended application.

Heat Treatment and Tempering

Once alloyed, the steel is cast and may undergo annealing to relieve internal stresses and improve malleability. For applications where hardness and strength are prioritized, the material is subjected to tempering—a controlled heating process that increases toughness and impact resistance without sacrificing flexibility. The careful control of temperature and cooling rates is essential to achieve the desired microstructure and mechanical performance.

Quenching, Hardening, and Finishing

Spring steel often undergoes quenching—rapid cooling in water, oil, or air—to lock in hardness and tensile strength. Air hardening is a cost-effective alternative to traditional water or oil quenching, offering similar performance benefits. Following heat treatment, the steel is cold drawn, rolled, or formed into sheet, strip, or wire stock. Additional finishing processes such as slitting, edging, leveling, and surface coating are used to meet precise dimensional and surface quality standards.

In some cases, post-manufacturing hardening or retempering is performed on finished parts to achieve optimal mechanical properties. Manufacturers may also add surface treatments, such as bluing or electroplating, to enhance corrosion resistance and extend the service life of spring steel components.

Specialized Manufacturing Techniques

Precision forming, stamping, and coiling techniques are often used to create complex geometries, such as helical springs, clips, retainers, and custom-shaped blanks. Sophisticated quality control processes, including hardness testing, tensile testing, and microscopic analysis, ensure that each batch of spring steel meets stringent industry and customer specifications.

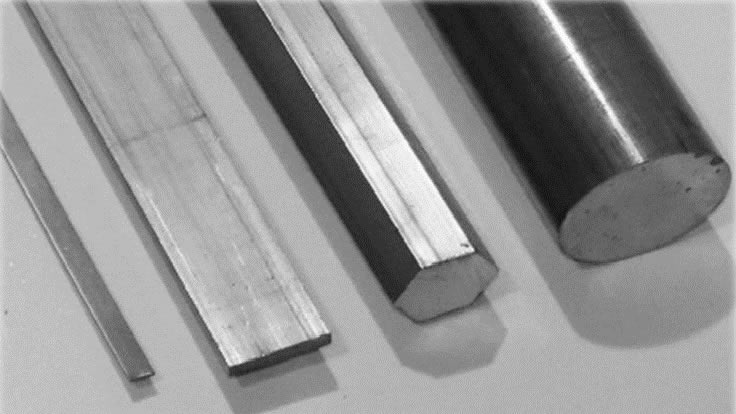

Types of Spring Steel

There are several common grades and types of spring steel, each tailored for specific uses and performance requirements. Understanding the differences can help buyers and engineers select the best material for their application:

- High Carbon Spring Steel (e.g., 1095, 1075, 5160): Offers excellent hardness, wear resistance, and the ability to maintain a sharp edge. Common in knives, tools, and heavy-duty springs.

- Alloy Spring Steel (e.g., 9260, 6150, 9254): Enhanced with additional elements for improved toughness, fatigue resistance, and corrosion resistance. Used in demanding automotive and industrial settings.

- Stainless Spring Steel (e.g., 17-7 PH, 301, 302, 316): Combines spring properties with corrosion resistance, ideal for medical, food processing, and marine environments.

- Music Wire: A high-tensile steel wire with exceptional fatigue life, used for precision springs, piano wires, and small mechanical assemblies.

- Blue-Tempered Spring Steel: Known for its distinctive blue oxide surface, this type is widely used in blades, flat springs, and measuring tapes due to its balance of hardness and flexibility.

Advantages and Benefits of Spring Steel

When evaluating materials for high-performance, fatigue-critical applications, spring steel offers a range of key advantages:

- Exceptional Elasticity: Stores and releases mechanical energy efficiently, enabling repeated bending, twisting, or compression without permanent deformation.

- High Yield and Tensile Strength: Withstands heavy loads and cyclic stresses, making it ideal for springs, fasteners, and load-bearing components.

- Superior Fatigue Resistance: Maintains performance and longevity even in applications involving millions of stress cycles.

- Versatility: Available in a variety of grades, forms (sheet, strip, wire), and surface finishes for diverse design and engineering needs.

- Cost-Effectiveness: Offers a high performance-to-cost ratio, particularly in mass-produced mechanical and automotive parts.

- Good Formability: Can be intricately shaped, stamped, or coiled, then hardened for optimal strength and flexibility.

- Corrosion and Wear Resistance: Select grades provide excellent resistance to rust and surface wear, reducing maintenance costs and extending service life.

The most distinguishing feature of spring steel is its ability to be coiled into a helix, storing energy when compressed and releasing it when expanded. This elastic property, combined with a balanced hardness that prevents breakage or fracture, makes spring steel the preferred choice for applications requiring ongoing mechanical movement and resilience.

Common Questions About Spring Steel

What factors should you consider when selecting spring steel for your application?

When choosing the right spring steel, it’s important to evaluate the required load capacity, fatigue life, environmental conditions (such as exposure to moisture or chemicals), desired hardness, and formability. The specific grade and heat treatment process must align with the mechanical demands and operating environment of the intended product.

Can spring steel be welded or machined?

Spring steel can be machined in its annealed state but becomes more challenging to work with once hardened. Welding is generally not recommended unless a subsequent retempering process is applied, as high temperatures can compromise the material’s properties. Most fabrication is therefore done before final hardening and tempering.

How does spring steel compare to stainless steel or tool steel?

While stainless steel offers superior corrosion resistance, and tool steel excels in wear resistance and cutting performance, spring steel is unrivaled in applications requiring high elasticity, fatigue resistance, and the ability to return to its original shape after deformation. Some stainless spring steels, however, can provide both spring properties and corrosion resistance.

What is the typical lifespan of a spring steel component?

With proper design, material selection, and heat treatment, spring steel components can withstand millions of stress cycles. Their actual service life depends on the specific application, loading conditions, and environmental factors.

Other Applications of Spring Steel

Spring steel's exceptional mechanical properties and versatility make it the ideal alloy for a vast array of advanced engineering applications beyond traditional springs. Examples include:

- Precision washers and shims for maintaining tight dimensional tolerances

- Snap-action electrical switches and connectors

- Safety lock components in firearms and security devices

- Orthopedic implants and prosthetic devices in the medical field

- Flexible couplings, bellows, and vibration-damping elements in machinery

Whether used in high-speed industrial equipment, consumer electronics, or critical safety devices, spring steel continues to serve as the backbone of modern mechanical engineering and design.

Choosing the Correct Spring Steel Supplier

With the strategic role that spring steel plays in so many industries, selecting the right spring steel supplier is crucial for ensuring both material quality and performance. To make sure you have the most positive outcome when purchasing spring steel from a spring steel supplier, it is important to compare at least 4 companies using our spring steel directory. Each spring steel supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each spring steel business website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple spring steel companies with the same quote.

Factors to Consider When Evaluating Spring Steel Suppliers

- Material Certifications: Ensure the supplier provides full material traceability, mill certificates, and compliance with industry standards (e.g., ASTM, SAE, DIN).

- Custom Processing Capabilities: Look for suppliers who offer value-added services such as shearing, slitting, edging, tempering, or surface coating, enabling you to receive material ready for your manufacturing process.

- Range of Grades and Forms: A reputable supplier will carry a broad inventory of spring steel grades, thicknesses, widths, and forms (sheet, strip, wire, bar, plate), tailored to your specifications.

- Quality Assurance: Consider companies with robust quality control programs, including in-house testing and inspection, to guarantee material consistency and performance.

- Lead Times and Logistics: Fast turnaround, reliable delivery, and flexible ordering options are essential for minimizing production downtime.

- Technical Support: Suppliers with knowledgeable technical staff can help you select the optimal spring steel grade and processing method for your application.

- Cost Competitiveness: While price is important, consider the total value offered—including quality, service, and reliability—when choosing your spring steel partner.

For buyers, engineers, and procurement professionals, leveraging a comprehensive directory of spring steel suppliers ensures access to a diverse range of products and services, improving sourcing efficiency and reducing risk. Whether you are seeking standard sizes or custom-engineered spring steel solutions, working with a trusted and experienced supplier is key to achieving optimal results in your projects.

Conclusion: Why Choose Spring Steel?

Spring steel remains one of the most versatile and indispensable materials in modern industry, offering a unique balance of strength, flexibility, fatigue resistance, and cost-effectiveness. Its ability to absorb energy, withstand repeated mechanical stress, and return to its original shape makes it the material of choice for applications ranging from automotive and aerospace to precision instruments, consumer products, and medical devices.

If you are seeking a material that delivers both performance and value, spring steel’s wide array of grades, customizable properties, and proven reliability make it a preferred choice for demanding engineering challenges. By understanding its unique characteristics, manufacturing processes, and application-specific benefits, you can confidently select the best spring steel solution for your needs—and partner with the right supplier to ensure long-term success.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services