Galvanized steel articles are coated with one or more layers of zinc in order to improve strength and corrosion resistance in industrial, commercial and domestic applications where steel parts are exposed to corrosive materials or are in high use. Read More…

Delta Steel is a leading provider of high-quality steel products, offering a comprehensive range of steel solutions to meet the diverse needs of our customers. With a commitment to excellence and reliability, we supply a wide variety of steel products for construction, manufacturing, infrastructure, and other industries.

At Delaware Valley Steel, we take pride in being one of the region’s most trusted steel service centers. We have built our reputation on precision, reliability, and the ability to deliver high-quality materials tailored to the unique needs of our customers.

At Grand Steel Products, Inc., we are a leading provider of steel service center solutions, offering a comprehensive range of products and services to meet the diverse needs of our clients. With years of experience and a commitment to excellence, we have established ourselves as a trusted partner in the steel industry, delivering reliable solutions that optimize supply chain efficiency and meet...

More Galvanized Steel Service Centers

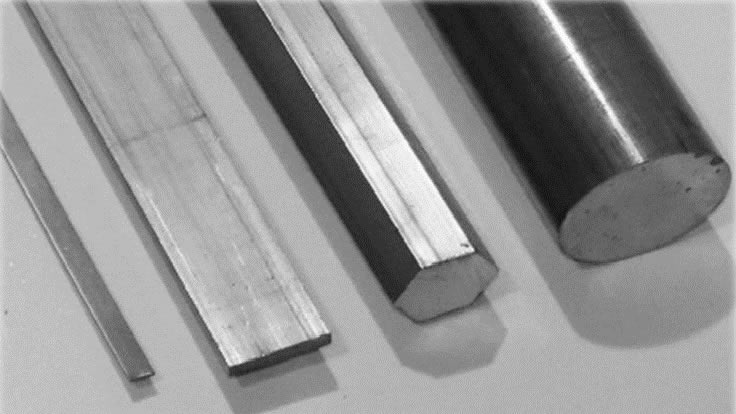

Steel, composed predominantly of iron, is among the most common alloys in the world. In addition to iron and carbon, other metallic elements are introduced to create unique alloys with application-specific properties. Galvanization enhances these qualities by forming a metallurgical bond between the steel and zinc. This not only improves tensile strength but also provides an added layer of protection. While this layer, varying in thickness from one mil to just over four mils, will eventually corrode, the damage is significantly slowed.

The application of zinc is a relatively simple and cost effective procedure, making its use popular for a variety of steel hardware and fixtures such as grills, grids, grip plates and grates, nails, braces, screws, beams, studs and even automotive paneling. A wide variety of industries make use of the prolonged lifespan of galvanized steel parts. Construction, automotive, electronic, shipbuilding, aerospace, marine, chemical and food processing, power generation, water treatment and several other applications utilize galvanization to ensure the quality and safety of finished products.

Galvanization is most often achieved through a process known as hot-dip galvanizing. Essentially, this involves bathing steel components in molten zinc. Zinc is kept liquefied at temperatures near 860°F. The metal articles, first cleaned with a light acid solution, are either dipped or fed into the zinc bath, which forms a permanent bond with the substrate materials.

When exposed to oxygen and carbon dioxide in the atmosphere, the zinc is cured and forms a layer of zinc carbonate that further protects the steel products. While traditional hot-dipping is still widely used, two additional techniques are growing in use and popularity. Electro-galvanizing passes an electric current through the zinc compound in order to create a thinner and more tightly bonded coating.

The newest development is the environmentally-friendly thermal diffusion galvanizing, which eliminates the hazardous caustic and acid baths used in traditional methods. Rather than a molten bath, zinc powder is applied to steel parts that are then sealed in a drum and processed through a rotary oven.

Zinc can be applied in single or multiple layers depending upon the steel's intended use. Each technique results in spangle, either uniform or large grain, on the finished product. Spangle is the appearance of a crystalline structure that gives the formerly shiny metals a dull grey appearance. Galvanization is most often applied to pre-formed ready-for-assembly parts, though some steel service centers provide stock shapes as well.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services