With carbon making up the second-largest component after iron, carbon steel is an alloy of metals that varies in hardness and strength depending on the amount of carbon added. Although the phrase “carbon steel” is used more widely to refer to all iron and carbon steel alloys where the presence of other metals is limited, the American Iron and Steel Institute has a fairly rigorous definition of carbon steel and permissible content levels for extra elements. Read More…

Delta Steel is a leading provider of high-quality steel products, offering a comprehensive range of steel solutions to meet the diverse needs of our customers. With a commitment to excellence and reliability, we supply a wide variety of steel products for construction, manufacturing, infrastructure, and other industries.

At Delaware Valley Steel, we take pride in being one of the region’s most trusted steel service centers. We have built our reputation on precision, reliability, and the ability to deliver high-quality materials tailored to the unique needs of our customers.

At Grand Steel Products, Inc., we are a leading provider of steel service center solutions, offering a comprehensive range of products and services to meet the diverse needs of our clients. With years of experience and a commitment to excellence, we have established ourselves as a trusted partner in the steel industry, delivering reliable solutions that optimize supply chain efficiency and meet...

More Carbon Steel Service Centers

Under their classification, carbon steel is essentially any steel not requiring nickel, cobalt, chromium, tungsten, zirconium, niobium, titanium, vanadium, or molybdenum as an alloying agent.

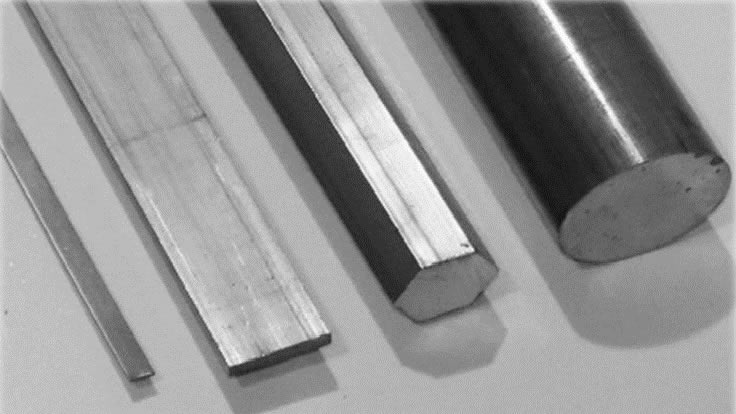

Carbon steel is a particularly hard ferrous metal in general. The characteristics of a certain alloy change depending on the carbon percentage. Low levels of carbon produce alloys with characteristics that are very similar to those of pure iron, but as the content rises, hardness, corrosion resistance, and strength increase proportionately. However, high carbon levels reduce material flexibility, thermal resistance, melting point, and production options. Steel service centers supply this material to various industries, including building and architecture, automotive, electronics, aerospace, and power generation. Many producers buy stock shapes such as bars, rods, tubes, plates, sheets, strips, foil, wire, billets, slabs, and blooms; however, some service centers only offer finished goods. For use in powder metallurgy, ingots, and powders are additionally offered.

Types of Carbon Steel

Low-Carbon Steel

Low-carbon steel usually contains between 0.04% to 0.30% carbon. This classification is the largest subcategory of carbon steel. It encompasses various shapes, including structural beams and flat sheets. Depending on the desirable qualities needed, other ingredients are reduced or enhanced. It is soft, malleable, and flexible. Its main products include steel bars, stamping-resistant components, certain steels, etc. Increasing the surface hardness of low-carbon steel through the carburizing process makes it more abrasion-resistant and gains even more strength.

Low–Carbon Steel Characteristics

- extreme toughness

- mediocre tensile strength

- extremely weldable

- cheap

- very ductile

- softness

- extremely machinable

Medium-Carbon Steel

It typically contains between 0.31% and 0.60% of carbon and 1.060% to 1.65% of manganese. It is stronger than low-carbon steel but more difficult to mold, weld, and cut. Medium carbon steels are frequently hardened and tempered by heat treatment. Medium carbon steel is perfect for making items like gears and studs that will withstand a lot of wear and tear. If more hardening is required, medium carbon steel can be heated and kept at a steady temperature until it reaches the requisite hardness, then soaked and cooled. Medium-carbon steel is used to produce stainless steel.

Medium-Carbon Steel Characteristics

- moderately strong

- reasonable toughness

- moderately weldable

- low ductility

- minimally machinable

- low-alloy steel

High-Carbon Steel

It typically goes by "carbon tool steel," and its typical carbon content ranges from 0.61% to 1.50%. High-carbon steel is very difficult to cut, bend, and weld. After being heated, it becomes incredibly brittle and rigid. Chromium and manganese alloys can be added to high-carbon steel during manufacturing to help the material withstand corrosion.

High-Carbon Steel Characteristics

- extreme toughness

- mediocre machinability

- high power

- reasonable weldability

- minimal ductility

Ultra-High Carbon Steel

It has a carbon content ranging from 1% to 2%. As a result, it is used to create extremely hard components.

Applications of Carbon Steel

Low-carbon steel is often produced as flat-rolled sheets and strips for domestic appliances, wire, automobile bodywork, and shipbuilding. In addition, it is frequently used for fabrication and paneling since heat treatment cannot change it. Wrought iron is a type of carbon steel with the least amount of carbon and is used to make fencing, gates, and railings.

The quality of medium carbon steel is enhanced by adding trace amounts of silicon and manganese. It is frequently used structurally in buildings, bridges, cars, refrigerators, washing machines, axles, gears, shafts, railroads, pipelines, and couplings. It is also known as mild steel.

High carbon steel, which is used to create cutting tools, blades, punches, dies, springs, and high-strength wire, has a substantially superior tensile strength.

Because it is so hard and brittle, ultra-high carbon steel cannot be cold-wrought. Extremely durable components including blades, cutting tools, rails, general bearings, massive machine parts, industrial castings, metal lamp posts, and hot water radiators are all made using ultra-high carbon steel. Old-fashioned cooking pots are made of this material, also called "cast iron."

Benefits of Carbon Steel

- Durability. It is useful for building projects since it is dependable and shock-resistant. Compared to other building materials, including those used to construct homes, offices, and governmental facilities, carbon steel constructions are more resistant to natural disasters like earthquakes and tornadoes.

- Sustainability. Reusable, recyclable, and sustainable all describe carbon steel.

- Affordability. Some goods can be produced for significantly less money with carbon steel because it can be worked much more effectively than other metals.

- Safety. Handling carbon steel is generally simple and secure. Because it does not release potentially dangerous compounds into food, it is frequently used in cookware.

Choosing the Right Carbon Steel Supplier

To make sure you have the most beneficial outcome when purchasing carbon steel from a carbon steel supplier, it is important to compare at least 4 companies using our list of carbon steel suppliers. Each carbon steel supplier has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each carbon steel company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple carbon steel companies with the same form.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services