One of these types of tubing is called seamless tubing, where extrusion or rotary piercing is used during the production process. Read More…

Delta Steel is a leading provider of high-quality steel products, offering a comprehensive range of steel solutions to meet the diverse needs of our customers. With a commitment to excellence and reliability, we supply a wide variety of steel products for construction, manufacturing, infrastructure, and other industries.

At Delaware Valley Steel, we take pride in being one of the region’s most trusted steel service centers. We have built our reputation on precision, reliability, and the ability to deliver high-quality materials tailored to the unique needs of our customers.

At Grand Steel Products, Inc., we are a leading provider of steel service center solutions, offering a comprehensive range of products and services to meet the diverse needs of our clients. With years of experience and a commitment to excellence, we have established ourselves as a trusted partner in the steel industry, delivering reliable solutions that optimize supply chain efficiency and meet...

More Seamless Tubing Service Centers

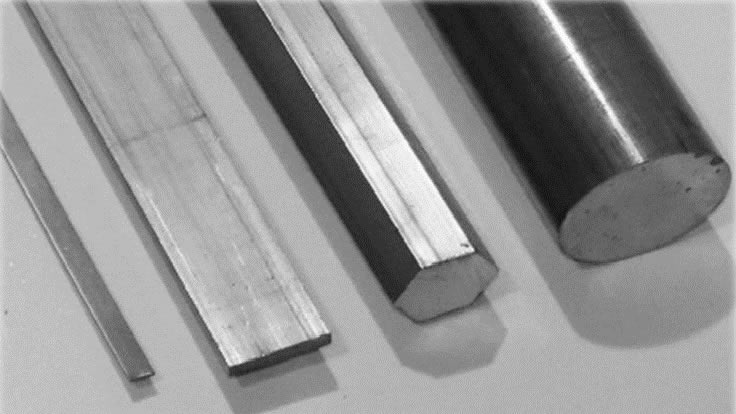

A seamless pipe is created by drawing a solid billet over a piercing rod to create a hollow shell. Most seamless tubing is pulled through a die that reduces its diameter in the final stages of manufacturing. This yields a strong product, and without any welding lines you are left with a tube that is less susceptible to corrosion and has no weak points in its structure.

To control the wall thickness, a plug is inserted into the tube while it is being drawn. This plug moves through the tube as pressure is applied, keeping the wall thickness even throughout the tube.

Seamless tubes are used in almost every industry, from construction to agriculture to healthcare. Many hand rails and guardrails are simply pieces of seamless tubing. A seamless tube is light and rigid so that it can easily be cut and installed in a wide variety of applications.

Steel is often used to create seamless tubes, but they are also made out of ceramic, fiberglass, other metals and even concrete or plastic. Obviously plastic is the most malleable of the materials, and this is most commonly used for applications where some flexibility in the tube is required.

Seamless tubes can be bent during manufacturing to create 90 degree angles if they are being fitted to a particular product. Plastic seamless tubing is becoming much more popular because it is light weight, chemical free and non-corrosive. It can easily be cut and connected for a wide variety of uses.

Tube sizes are measured based on the diameter on the outside of the tube. As pipes have improved, the walls have become thinner while still remaining strong, creating a larger internal diameter which allows for more flow. The primary advantage of using a seamless tube is that it is able to withstand a much greater amount of pressure because of the equal strength around the circumference. The seam in a traditional welded tube makes it much more vulnerable to bursting when high pressure volumes pass through it.

Alloy Suppliers

Alloy Suppliers Aluminum

Aluminum Aluminum Extrusions

Aluminum Extrusions Copper-Brass-Bronze

Copper-Brass-Bronze Magnets

Magnets Nickel

Nickel Stainless Steel

Stainless Steel Stainless Steel Tubing

Stainless Steel Tubing Steel Service Centers

Steel Service Centers Titanium

Titanium Tungsten

Tungsten Wire Rope

Wire Rope Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services